WHAT IS GEOPOLYMER CONCRETE?

Geopolymer concrete represents a groundbreaking advancement in sustainable construction materials, distinguished by its cement-free composition. The binder in this innovative concrete is made from industrial by-products, including fly ash and iron slag, diverting waste from landfills and reducing reliance on traditional cement. Notably, geopolymer concrete significantly lowers CO2 emissions compared to conventional concrete, addressing one of the construction industry's most pressing environmental challenges. Moreover, it doesn't compromise on performance; it offers reliable mechanical strength and durability, making it suitable for a wide range of applications. Another significant advantage is its resistance to many common forms of degradation that affect traditional concrete, such as sulfate attack, making it an ideal choice for more durable and environmentally friendly construction projects.

Several corporations worldwide are at the forefront of developing geopolymer concrete products, including Betolar in Finland, a pioneer in the field, as showcased in their informative video.

Novel Iron Ore Tailing-Based Geopolymer Concrete

Fly ash, a common binder in geopolymer concrete is becoming increasingly scarce as coal power stations are phased out worldwide. Our geopolymer solution innovatively uses iron ore tailing as a main binder combined with iron slag to address this challenge. Iron ore tailing, widely available in many countries, currently lacks specific applications and is often merely dumped, posing environmental threats. Utilizing it offers a sustainable solution to waste and ensures the accessibility and environmental friendliness of our geopolymer concrete compared to traditional fly ash-iron slag-based and conventional Portland cement-based concretes.

This product's unique mixture is ideally suited for semi-dry concrete production, a process that notably reduces the alkaline source-to-binder ratio. This reduction not only enhances the concrete's sustainability aspects but also improves its mechanical and durability features. Utilizing this technique, we currently produce a pervious (permeable) geopolymer paver, branded as Geo Plus. This method not only contributes to environmental sustainability but also offers advanced solutions for water management and managing urban runoff through its permeability.

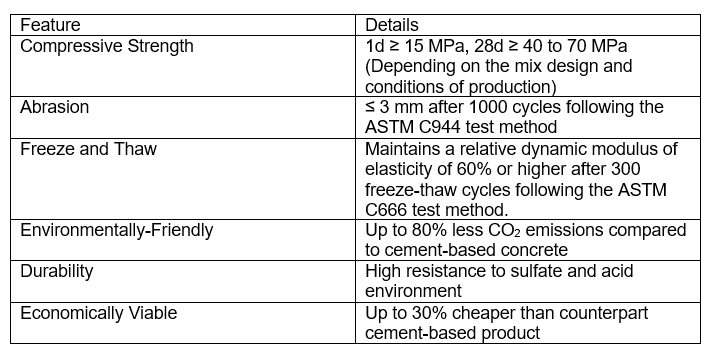

Improved durability, reduced CO2 emissions, and cost-effectiveness, emphasizing the sustainability and efficiency of the iron ore-based geopolymer concrete.