Self-healing concrete

Self-healing concrete introduces a transformative approach in the concrete industry, enhancing structural durability and sustainability. This technology addresses the perennial challenge of crack formation, utilizing either the concrete's inherent autogenous healing capabilities or incorporating specific additives that activate repair mechanisms to seal cracks autonomously. Such advancements extend the lifespan of concrete structures, reducing the need for frequent repairs and associated environmental impacts. By diminishing material consumption and maintenance activities, self-healing concrete significantly lowers CO2 emissions, contributing to greener and more resilient urban infrastructures and aligning with efforts to combat climate change.

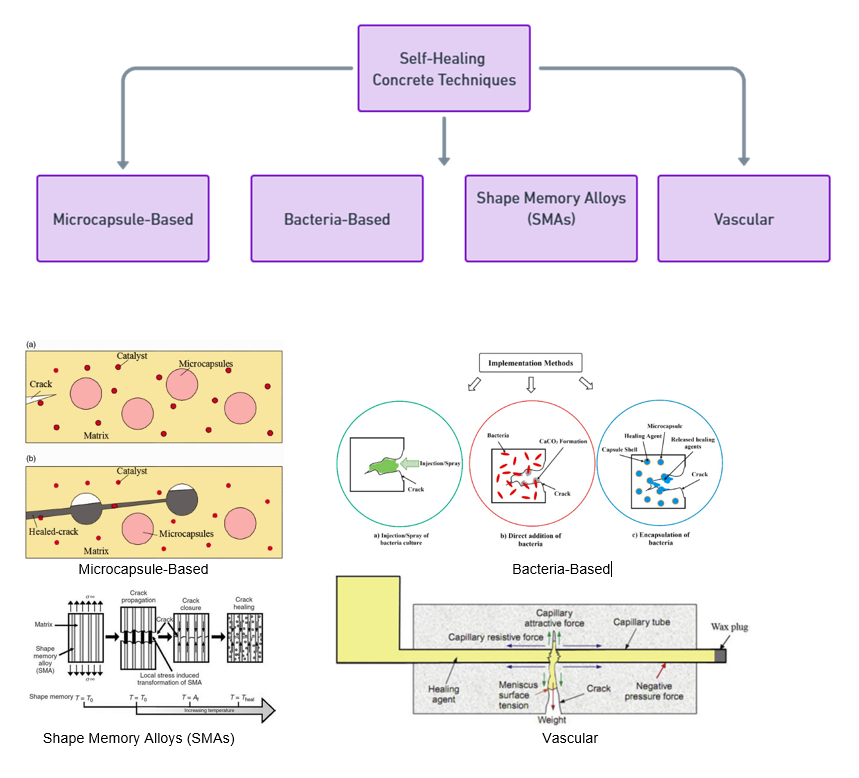

innovative self-healing concrete techniques.

Microcapsule-based healing embeds repair agents within tiny capsules, which break open to seal cracks as they appear—offering precise healing, albeit with a limitation in capsule life span.

Bacteria-based methods utilize natural microorganisms to produce limestone, effectively mending cracks with an eco-friendly touch, although their efficacy may vary with environmental moisture levels.

Shape Memory Alloys (SMAs) are smart materials that 'remember' their original shape, contracting to close cracks upon specific triggers, providing a robust solution with higher implementation costs.

The vascular technique draws inspiration from natural healing processes, circulating healing agents through a network of channels to the damaged areas and ensuring continuous repair capabilities with more complex integration.

Leading research institutions globally are advancing self-healing concrete technology to enhance the longevity and robustness of construction materials. The Resilient Materials 4 Life (RM4L) project, a collaboration among prominent UK universities, is investigating a spectrum of self-healing technologies to revolutionize the building industry.

Nanoparticles-Based Core-Shell Self-Healing

Current self-healing concrete technologies are advancing but face limitations. They are typically only effective for micro-cracks, not larger ones exceeding 1 mm. Economic feasibility also poses a significant challenge, as laboratory processes and the associated costs can make these technologies prohibitively expensive.

However, the encapsulated nanoparticles-based self-healing cementitious technology offers distinct advantages:

-

Utilizes waste glass, promoting a circular economy.

-

Ensures a high survival rate of self-healing agents during the casting process.

-

Capable of healing cracks up to 2 mm in width.

-

Achieves a lower initial cost and is less dependent on ambient moisture for activation, offering an advantage over bacteria-based methods.

"This innovative technology is a milestone in creating sustainable, cost-effective self-healing concrete with proven durability."

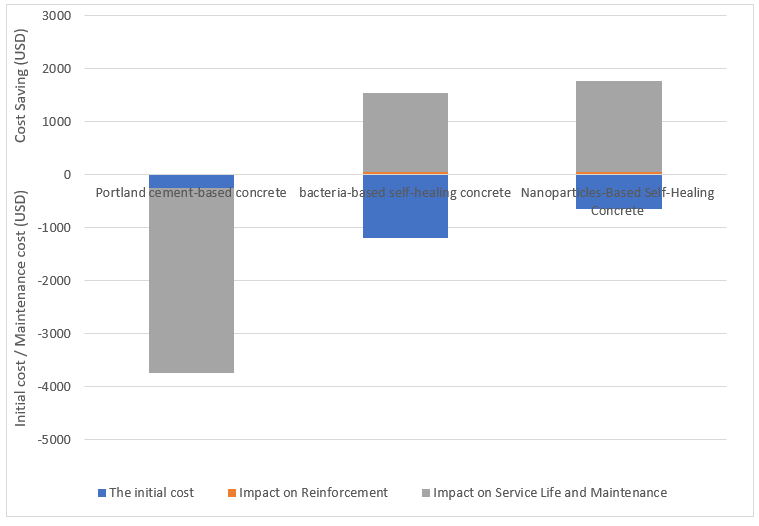

Upfront costs for Portland cement-based concrete are lower; however, it accrues higher lifetime maintenance costs (Negative Impact), totaling around a $3,000 loss per cubic meter.

Self-healing concretes, including bacteria-based and nanoparticle-based varieties, substantially lower lifetime maintenance and reinforcement costs (Positive Impact)

Our nanoparticle-based self-healing concrete outperforms other types, with an overall savings of $1,000 (deducting the initial cost) per cubic meter over a 30-year lifetime.

While self-healing concrete options present a higher initial cost, they offer considerable reductions in long-term maintenance and infrastructure lifecycle expenses.

Self-healing properties permit designs with up to 40% less shrinkage reinforcement, accommodating larger crack widths efficiently.

Enhanced self-healing capabilities extend service life and reduce maintenance needs, resulting in substantial cost savings over time.